Dual Points in a Buick Straight 8 Distributor

INSTRUCTIONS :

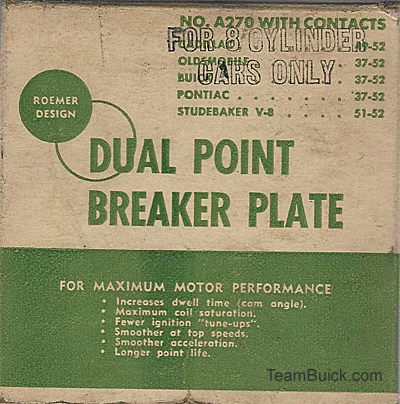

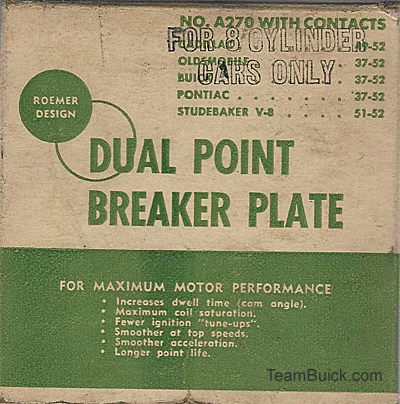

INSTRUCTIONS : A 270 DUAL POINT BREAKER PLATE -8 cylinder motors only

- Remove distributor cap and note position of rotor.

- Remove entire distributor (and place in bench vice for convenience).

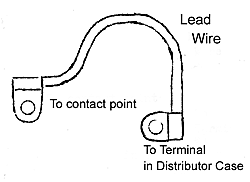

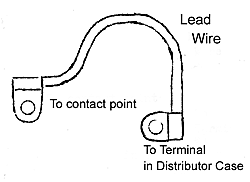

- Remove vacuum control, bale screws, primary terminal block and leads (through side of distributor housing).

- Remove old plate.

- Remove condenser.

- Place new A 270 plate in distributor housing so screw holes and plate line up with holes in housing.

- Place original ground lead over bale screw same as original setup and screw on bales. This holds plate in place.

- Replace primary wire lead and terminal block. Install vacuum control and arm onto plate and connect ground wire to screw which holds the vacuum arm.

- Remove paint on outside of distributor around screw nearest primary terminal block (for better electrical contact).

- Reverse clamp band around condenser and attach condenser to outside of distributor with screw nearest terminal block (referred to in No.9).

- Space new points .025" each. This wide spacing allows for initial wear of fibre blocks during first 1000 miles. Respace points at .018" each after first 1000 miles.

- Lubrication - place light grease on cam and fibre blocks before operation. DON'T allow cam to run dry and DON'T use excessive amounts of grease.

- Install distributor in motor -CHECK ROTOR POSITION PER NO.1 BEFORE INSTALLING.

- Start engine and adjust timing as needed - use timing light.

WARNING : Damage to plate may result from use of long screws. Pressure of screw against side of plate may prevent free movement. REMEDY: use shorter screws or extra washers.

NOTE : Circuit is opened by contact point nearest vacuum control diaphragm. To set points on testing machine, block off one set of contacts with paper card between the points and set the other contact point at 280 cam angle. Repeat procedure for the second set of contacts and also set at 280. Cam angle is measured with both contacts operative.

INSTRUCTIONS : A 270 DUAL POINT BREAKER PLATE -8 cylinder motors only

INSTRUCTIONS : A 270 DUAL POINT BREAKER PLATE -8 cylinder motors only