from: Car Review, March 1985

from: Car Review, March 1985

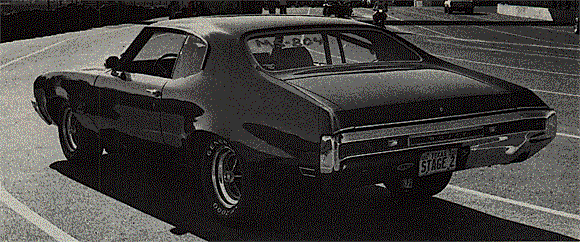

1. Painted a sedate blue, this 1970 Buick GS might look ordinary, but under the hood lies a rumbling Stage II 455 that's ready to thrash most challengers.

2.Dave Knutsen of Washington state made 10 pairs of these special Stage II emblems. They bear a resemblance to Buick's Stage I emblems, but were never distributed or offered by the division. A nifty little item, nevertheless.

3.Dual-snorkled 455 develops 535 hp, enough to pull the Buick through the quarter in 10.64 seconds at 124.65 mph.

4.The Buick wears stock rims and street rubber when Turner takes the street legal Stage II out for a cruise.

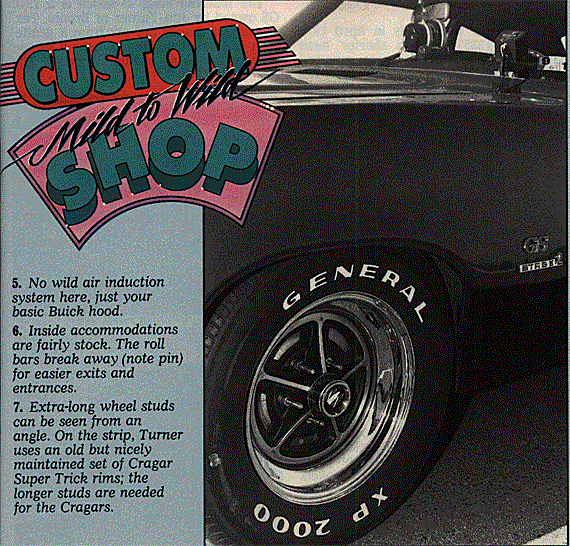

5.No wild air induction system here, just your basic Buick hood.

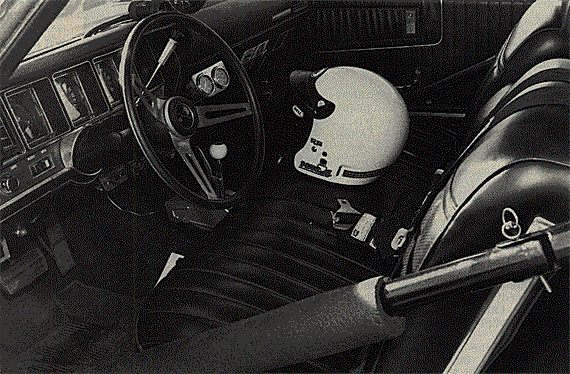

6.Inside accommodations are fairly stock. The roll bars break away (note pin) for easier exits and entrances.

7.Extra-long wheel studs can be seen from an angle. On the strip, Turner uses an old but nicely maintained set of Cragar Super Trick rims; the longer studs are needed for the Cragars.

Muscle cars didn't just suddenly appear after a brainstorming session by the marketing folks at various automakers in the sixties. The development of horsepower and performance required a long lead time, and Buick was no exception.

Buick had, for some time, offered performance engines for its street cars. In fact, the division's involvement in this field predates World War II. Buick offered compound carburetion (dual carbs) in 1941, which boosted its 320.2-cid straight-eight engine's horsepower to 165. As offered in the Century, Roadmaster, and Limited series, Buick's Fireball engine became one of America's most powerful power plants at the time. However, dual carbs would not again be found under the hood of a Buick until the 1965 Riviera Gran Sport was released.

The year 1953 witnessed the introduction of the 322-cid V-* for Buick, which spawned a whole series of engines for years to come. Affectionately known as the nailhead engine, the mill used a vertical valve arrangement that would be carried over to the 364, 401, and 425 engines. Its light weight (a block weighted 177 pounds), compact size (26,56 inches at its widest point, and thirst for high revs, (properly tuned, a nailhead could hit 6,000 rpm), made the engine a natural high-performance platform.

Buick produced engine kits for the 364 that would boost performance. But, the

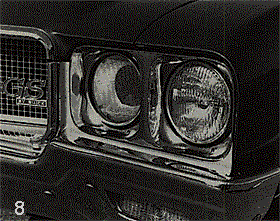

8. Real scoops poke through the hole where the high beams usually reside. From a distance, they're hard to detect.

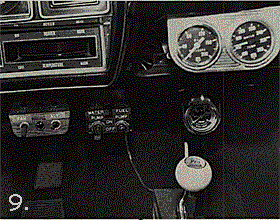

9. Horsepower-robbing items, such as the water

pump and fuel pump, are converted to run on electricity.

10. Pro-Comp II tach is mounted on the dash, a necessity if you want to hit those optimum shift points.

11. A Stewart-Warner fuel pressure gauge is mounted outside on the cowl, visible though the windshield.

kits were labeled as "export" items, since everyone knew that only the Europeans were interested in boosting the performance of their Buicks, right (wink, wink)? The kits included high-lift long-duration cams, solid lifters, high compression 11:1 pistons, and adjustable rocker arms. The updates added 30 hp, boosting the 364's output to 330 hp total.

One of the earliest drag race drivers to use a Buick to clip the quarter was Lennie "Pop" Kennedy. He started with a '55 Century and later racked up enough points in the National Hot Rod Assn. (NHRA) to place second. He won the '61 NHRA nationals with his Buick. With Jim Bell, Kennedy formed Kenne-Bell (based in Upland, Calif.) , which has since become the outlet for performance Buick products.

The last of the nailhead engines was the 425. In 1967, Buick released its new wedge engines, the 400 and 430. Following in the same tracks, the 455 wedge was released in 1970, with a standard horsepower rating of 350, and a very conservatively rated 360 hp for the Stage I engine.

While all this wonderful hardware was being offered to the public, Buick engineers (Dennis Manner was chief engineer) were working on the ultimate Buick performance option, the Stage II.

Ah, yes, the Stage II. It certainly ranks as one of Buick's most elusive options. Indeed, it's hard to even classify the Stage II as an option. Only a few well-connected racers ever got their hands on a Stage II package. Originally made in 1969 and 1970, complete Stage II packages (which included the heads) were not available to the public until 1972.

So, what exactly is a Stage II package? It's a number of engine performance items, and buyers were free to pick and choose what items they wanted. Available from dealers, Stage II parts could be installed by the dealer or the buyer. This, of course, can lead to some mayhem today, as anyone with even a single Stage II part on their Buick can attest. Fortunately, this murkiness has been resolved. The Buick GS Club of America today recognizes a Buick GS as being a Stage II only if it has the special Stage II heads.

From the start, completely new heads were envisioned for the Stage II package. The earliest Stage II heads were built strictly for testing by Buick engineering. In fact, no intake manifold was ever produced to fit them.

They were machined with intake tunnel-ports. Some sources indicate the exhaust ports were D-shaped, while others contend they had round ports like the later version. Early heads can be identified by vertical bosses near the end exhaust ports capped with small freeze plugs. No one knows how many early Stage II heads were built.

The later Stage II heads were produced in some semblance of quantity (around 75 sets). Buick informed dealers of the

Stage II heads' availability in April 1972 (part No. 1235714). Ten shorter head bolts (part No. 1238391) were required for the heads' installation. However, the project was eventually scrapped due to casting difficulties. These later Stage II heads can be identified by the lack of the aforementioned freeze plugs.

Approximately 10 to 20 Stage II head sets are accounted for within the ranks of the GS club. Other sets continue to be tracked by members. For example, one set of Stage II heads was found in Indiana. The owner had used them for circle track racing. Due to their rarity and the important part they play in performance, it's easy to see why the heads have become the litmus test for labeling a Stage II car.

While the later Stage II heads used the same basic intake port configuration as found on Stage I engines, the full-round exhaust ports were so severely altered that Buick engaged Kustom Headers of Flint, Mich., (no longer extant) to build a complicated two-piece header with 2.12 inch primary tubing (model No. 2399). Back pressure was reduced, and high-rpm performance increased accordingly.

Other parts of the Stage II package also helped performance, but over the years their relative importance has diminished.

For instance, the Stage II cam (part No. 1385557) was farmed out by Buick to five different companies (such as Crane and Mellings) . The cam rendered a 455 quite fussy on the street, as its wild grind was designed to run without mufflers. Lift was 0.455 inch for intake, 0.480 inch for exhaust, with a quoted 340-degree duration on intake, 360 degrees on exhaust, and 160 degrees of overlap. The cam gave a lumpy 1,000-rpm idle if nurtured, but there was little vacuum left for power brakes. It is an antiquated grind now, and preferable alternatives exist.

Stage II heads fit the 400, 430, and 455 blocks. Eleven to one pistons forged by TRW for Buick were available in three sizes, depending on the engine (400 cid, No. 1394179; 430 cid, No. 1394180; 455 cid with 12:1 compression and slipper skirts, No. 1394878). Such pistons are still sitting around gathering dust as they can only be used in new blocks with tighter bore clearances (no oversizes were available). In addition, an Edelbrock B4B intake manifold, and either a Holley 850 vacuum carb (later the mechanical Holley 850-cfm R·4781, both made for non class applications) or a Rochester Super Stock Q-Jet carb rounded out the Stage II package.

The rally pack (part No. 1394195) was highly recommended for Stage II applications. It consisted of a heavy-duty rear end suspension package, including a rear stabilizer bar and a 4.78 rear gear set.

The featured Stage II Buick is a 1970 GS owned by Jim Turner of Bronte, Tex. Turner purchased the car from a gentleman in Kennedale, Tex., where it served duty racing on an eighth-mile track. The

Buick had been sitting in the previous owner's backyard for three years, due to a blown engine (which was already disassembled). But, the treasure was in the trunk: a set of Stage II heads, six good carillo rods, a polished Edelbrock B4B manifold, and various other sundries. As Turner put it, "What a find!" Somehow, even that comes off as an understatement.

One fiberglass bucket seat occupied the interior, along with a 10-inch steering wheel. But, the rest of the interior somehow survived, and the odometer showed a mere 1,018 miles (one race at a time).

When Turner first tested the car, it suffered from a severe case of front-end lift from a standing start, sometimes raising as much as 2 feet. Turner set the car up differently and eliminated this problem ("If it is a problem," noted Turner. "I know most NHRA stockers and super stockers require that their cars do this.")

Last year, Turner reported the Buick's best time had been a 10.9 second E.T. at 122 mph with mufflers and a weight of 3,800 pounds, including the driver. "I feel the car should run 10.7s uncorked (sans mufflers) on a good day ... cool, good barometer, no headwind and so forth," said Turner. Well, Turner found the right conditions last March when he ran a 10.64 second E.T. at 124.65 mph in the quarter mile at Temple, Tex. "I had some good air. Everything was optimum except the track," said Turner. The Buick weighed in at 3,700 pounds even, 200 over the minimum. Turner ran it uncorked.

The engine is a '70 455 block, bored 0.030 inches and fitted with Arias pistons wearing total seal rings and stock rods,

|

1970 BUICK GS STAGE II |

||

GENERAL DATA |

Induction system: Rochester Quadrajet 4-bbl. Ignition system: 12 volt breakerless Fuel: Racing Exhaust: Dual 3.5" Flowmaster racing muffler system Valve configuration: Overhead Main bearings: 5 TRANSMISSION Type: Turbo- Hydramatic 350 automatic DIFFERENTIAL Type: Limited slip 12 bolt Ratio: 4.10 SUSPENSION Front: Upper (modified) and lower (stock) control arms, Koni adjustable shocks, Moroso Super Stock coil springs with travel limiters Rear: Right rear air bag, stock Monroe shocks |

FRAME Type: Unitized steel STEERING Type: Manual Ratio: 24, 28.6 overall Turning circle: 44' BRAKES Front/rear: 9.5" hydraulic drums Effective swept area: 268.6 sq. in. TIRES Type: M&H N-50 (front),Mickey Thompson slicks (rear) CALCULATED DATA HP/CID: 1.15 LBS/HP: 7.04 LBS/CID: 8.13 PERFORMANCE* Standing 1/4 mile: 10.64 sec. @ 124.65 mph Fuel mileage: 9 mpg (street) *Source: jim Turner, owner |

producing a 12.5:1 compression ratio. The bottom end is beefed up by being filled with "grout," and on the top side the cylinders are Q-ringed. The Stage II heads are fitted with copper head gaskets. The solid lift cam and rocker arms are from Lunati, as are the springs and lifters. Larger stud bolts have been installed in the heads and in the main bearings.

A Fisher harmonic balancer has also been installed. Veering from the Edelbrock, the 455 has a T/A Performance intake manifold with a Rochester Quadrajet carb. The oil supply lives in a homemade eight-quart oil pan. Turner used to run 20W-50 oil, but has found the light-weight 5W-30 helps shave some time off the E.T.s.

The original Kustom headers - though rusted - had to be relied upon since no other manifolds/ headers existed for Stage II heads. The headers were sent to R.E.F. Limited in Phoenix, Ariz., and duplicated. Eddie Browder of Ed's Machine Shop in Abilepe, Tex., fitted all the various pieces and made them live with one another.

The electrics are routed through a distributor made by Ray Anderson of Ballinger, Tex. It is a breakerless magnetic pick-up type with an MSD 7 AL2 amplifier.

To chisel at wasted horsepower, Turner installed two 12-inch electric fans and an electric water pump, adequate for street use and excellent for racing (and switchable via toggles inside the car).

Shifting chores are handled by a Turbo-Hydramatic 350 transmission modified by Phoenix Transmission in Weatherford, Tex. It's lighter than a Turbo-Hydramatic 400, has a "better" low gear, and still survives, says Turner. An ATI stall convertor is also in use.

Out back, a '65 Chevelle 12-bolt rear (1 inch narrower than stock) winds up the tires. It's strapped in with a Strange C-clip eliminator kit, required by the NHRA. The axle also runs with a Moroso Brute Strength carrier and Richmond 4.10 gears. One air bag is on the right rear, along with stock Monroe shocks.

Stock lower control arms are matched with modified upper control arms, all using solid bushings. Koni adjustable shocks were added up front with Moroso Super Stock springs. Turner also installed adjustable front-end travel limiters. On the strip, Mickey Thompson slicks (10.5 x 29.5 x 15 inch) and M & H N-50 street tires are used.

Inside, the stock interior has been revived. The car was ordered

without power steering and without a radio. It came with the standard interior (rare for a GS) with a bench seat and a column shift. In regard to the shifter, Turner notes, "I had to add the B&M floor shifter when the car got in the high 10s (E.T.) because I kept missing gears with the column shifter." A six-point roll bar with dual swing-out bars (for ease of entry) has been installed, a necessary safety item for drag racing.

The car is street legal, right down to the emergency brake. The backup lights work off the column shifter, and the brake self-adjusters are still intact. There are no hood scoops, fiberglass, Lexan, super-low rear gears, tubs for tires, or nitrous. Modified? Yes, but all within the spirit of a streetable car - one that turns in sub-11 second E.T.s.

Turner's Buick has been a Stage II for as long as possible, the switch being made when the heads became available in 1972. Very few Stage IIs are being raced today, but with relatively light modifications they can be coaxed - as shown here - into real performers. It looks like those Buick engineers were onto something after all.