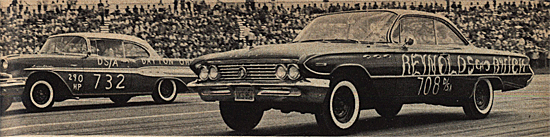

IN this chapter we will deal with the Buick engine in its stock form, touching on modification points that are permitted for the drag strip. Major modifications for the Special V8 have already been covered in a preceding chapter, and we'll discuss major modifications for the big V8 in the chapter that follows.

Meanwhile, whether your particular interest centers around competing at the drags or just having an engine that performs at its maximum potential on the highway, tuning methods discussed here will apply. Some of the major tuning methods discussed may fall in the realm of modifications which, in a sense, they are. But such modifying (which qualifies as tuning according to NHRA rules) is permitted since it does not involve the actual altering of components. Instead, it deals with going completely through the engine and correcting any variations from precision specifications that are always bound to occur with mass production. Setting an engine to exact specs on an assembly line is both costly and time consuming, and so manufacturers instead stay within certain tolerances which allow some leeway on the plus or minus side. These are the points that can and should be adjusted for best performance.

Before we get into major tuning, however, let's examine the possibilities of gaining some performance through minor tuning. The starting point here, naturally, would be with carburetion and ignition. Obviously, since we are talking about stock tuning, we have to stick to stock carburetion which, on the hotter Buicks is a single four-barrel.

Two of the throats serve as primaries while the remaining two are secondary which are set up to come in at high speeds for the additional air and fuel supplies needed within the combustion chamber. For economy purposes, the stock Buick carb has leaner jets in the primaries, since they are used for cruising at speeds near or below 40 mph. For drag racing, where full power is applied at the starting line, it usually is necessary to richen the mixture by going to larger size primary jets. Such things as atmospheric conditions, altitude, etc., have a bearing on how rich or lean a mixture should be so there is no set jet size to be recommended. Instead, it has to be a trial and error method, beginning with one stage richer and going up or down until the best results are obtained.

However, a good rule to remember is that the mixture must be rich enough to supply maximum energy to the pistons but not too rich so as to prevent clean, even burning. It must be on the lean side of the maximum power ratio of air/ fuel mixture so the engine can accelerate quickly. Too rich a mixture will cause the engine to become sluggish and a decrease in rpm and consequently speed and ET will result. Incidentally, NHRA drag rules permit the use of any jet size.

The two-barrel carburetor found on some Buicks has been designed mainly for economy. However, these can be made to do a better performance job by drilling the power jet orifice approximately .003 larger for a bit richer mixture under heavy acceleration. Some playing can be done with flat level setting, but

this should not vary too much from factory recommendations.

In any case, whether you're running a two- or four-barrel, another rule of thumb at the drag strip is that dense, cool air calls for an increase in jet size. When the weather is hot and dry, a smaller jet usually works better. Here again, the trial and error method is best according to conditions, and you're better off to make small changes each time rather than to go overboard either way.

For street operation, of course, carburetion mixture should be richer than that used for short, quarter-mile acceleration runs which make up the sport of drag racing, so the combination that works well at the strip may not be the answer for highway running where the richer mixture helps keep the combustion chamber cool.

It goes without saying that cleanliness and special care in disassembling or assembling a carburetor are musts. A slip of the screw driver can cause scratches or burrs which will impede the flow of the fuel/air mixture, cause the floats to hang up or prevent the needle valve from seating properly. Any such imperfections should be removed along with any sign of dirt or grit.

One of the welcome loopholes in NHRA drag rules is that any type of battery-operated ignition is permitted. While the stock Buick ignition is efficient and dependable, considerable advantage can be gained with some of the optional ignition accessories now available through speed shops, such as dual coil, dual point units. When these are used, however, considerable care should be taken in setting the breaker point gaps. Under no circumstances should they be set by blocking off one set and setting the other. This pushes the cam-shaft angle off center due to point spring pressure and when the points are released the cam angle will change on the one set first. It is best just to disconnect the wire connecting both points and set each one individually, while both points work against the distributor cam.

Regardless of the type of ignition you use, stock or otherwise, there are some basic maintenance points that should be observed. The counterweights must be free in the distributor, the shaft and bushing should be checked for wear and free movement, the points must be properly aligned and the rubbing block should be trued, especially when installing new points. Spring tension on the breaker points also is important and should be checked regularly, especially if the engine is used in competition. Improper tension allows the rubbing block to float away from the cam lobe, preventing uneven cylinder firing through the rpm range. All Buick mills, including the V6 have a recommended spring tension of 19 to 23 ounces and are best set on the high set for Competition.

Condensers seldom give trouble on an engine but, once in a while, one with the wrong capacity will show up and cause excessive point wear and possible minute misfiring. It is always wise,

when seeking maximum performance, to check condenser capacity to make sure it checks out with factory specifications. It can be checked on a distributor strobe which should be used when setting the cam angle for the proper advance rate.

The advance curve is important to any type of operation because it determines the length of time the air/ fuel mixture has to burn in relation to piston position. Actually, what we try to accomplish is to cause maximum pressure against the piston head on the power stroke, when the piston starts down. Too much advance, however, ignites the mixture too early and causes pressure to be exerted before the piston reaches the top of its compression stroke. Excessive detonation usually results.

On the other hand, if too little advance is used, the mixture is ignited too late and the piston is past TDC too far to take advantage of the combustion pressure. And the further down the piston moves the more effectiveness the pressure loses.

The way to get correct spark advance at both low and high speeds is to find the initial lead that gives the best low end performance, and then limit the automatic advance mechanism in the distributor so that the maximum degree is correct for high engine speeds. With the Buick engine, recommended initial timing-7.5 degrees at 1050 rpm for the V6 and aluminum V8 and 12 degrees BTC at 400 rpm for the big V8's-has been found to be close to correct for the drag strip.

Some competitors use more on the theory that the more initial lead you have the better the car comes off the line. This is partly true, but it must be blended into a curve that is correct for top end power also. For the best and most accurate curve, the distributor should be placed on a Strobe and checked out electronically. The rate of advance can be totally controlled by increasing or decreasing spring tension on the distributor counterweights.

Timing, of course, should never be done by guesswork. It is necessary to use a timing light for accuracy, and most competitors who run consistently well go a step further by having the harmonic balancer "degreed" for really accurate reading. Most machine shops are equipped to do this and it involves stamping the balancer in one degree increments for easy reading.

Spark plugs are one of the most important components to good performance and efficiency and therefore should receive careful attention. Choosing the right plug with the correct heat range that is

compatible with the type of driving encountered is very essential and should be complemented by proper cleaning and gapping. Some drivers swear by one brand while others are partial to another make. We won't go into a lengthy discussion here on the merits of one brand over another. All of the top manufacturers, Champion, Autolite, AC, etc., have been in the business a long time and all produce dependable products so we'll leave the brand choice up to the individual. It has been found, however, that the plugs recommended by the manufacturer generally are best suited to an engine.

Buick recommends AC plugs for all its engines, with varying recommended heat ranges. The V6 for example lists the AC 44S as its standard plug while the 155-hp aluminum V8 lists the 45FFS and the Skylark V8 lists the 44FFS. For the big V8's, the AC 44S is recommended. These are basic recommendations, however and, as pointed out, will vary according to the driving conditions. For sustained high speed running, for example, a colder plug definitely should be used, while at the drag strip the basic plug may prove to be just what the doctor ordered. Generally, one step colder than the recommended plug works well at the strip, and a .032 gap works well for both strip and street. For sustained high speed running it may be necessary to close the gap to .028 or .030. Some experimenting usually provides the right answer.

Reading plugs to determine whether the carburetor mixture is too lean or too rich has many advantages if you know what to look for. It is a practice that has become exceedingly difficult with the more recent power tip innovations which place the porcelain portion of the plug almost in the combustion chamber. In order to read a plug correctly, it is necessary to get it out of the engine immediately after a run, after the engine has been cut clean. That is, turning off the ignition while the engine is at high speed and slipping the transmission out of gear. If the car is allowed to decelerate with the ignition on or the crankshaft is still rotating, temperature loss and effects of the richer idle mixture will cause a false reading.

Immediately after the car has stopped the plugs should be pulled and read. If the mixture is too lean there won't be any carbon on the insulator, and the insulator may show an indication of overheating with a shiny, glazed appearance and a very light tan color. If the mixture is too rich, the insulator will have a wide band of carbon around it that is black in color. The correct mixture usually will bring out a narrow band of dull black or grey carbon deposit around the' insulator where it joins the shell.

Incorrect heat ranges also can be determined by reading the plugs. When it is correct, the plug will be free of deposits and will take on a nice light chocolate or tan color. Too cold a plug will be indicated by dull surfaced deposits around the insulator which can cause fouling while too hot a plug will be indicated by a cracked or split insulator or one with shiny deposits around it.

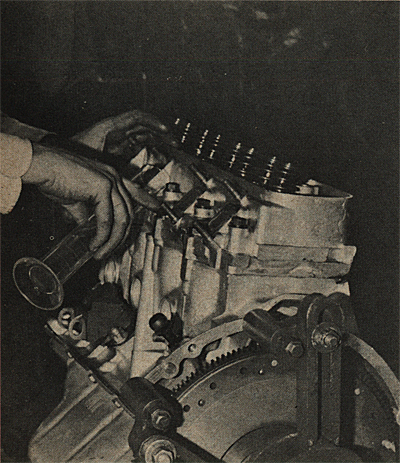

That pretty well covers some of the basic or minor tuning which can add to the Buick's overall performance. Additional gains are possible through the use of exhaust headers but, unfortunately, ready-made units for the Buick are hard to come by. Many owners wind up fabricating their own or having the work done at specialty shops.For someone going the full route on major tuning by placing all components at their exact specifications and taking advantage of factory tolerances, it is first necessary to completely disassemble the engine so that various parts can be checked. The amount of variations found will dictate the amount of re-working necessary, and it usually involves machining and reworking with special tools and equipment. It can

be-come costly but can hardly be passed up if maximum performance is the ultimate.

One of the initial areas to check is deck clearance, which is the distance from the top of the piston to the top of the cylinder block when the piston is at top dead center (TDC). Since this affects accurate compression ratio it is important that it be made to conform with exact specifications, and you will generally find that the specified deck clearance is off from that specified.This can be due to a number of reasons. There may be a variation in the crankshaft; the connecting rods may not all have the exact same length when measured from center to center; compression heights of the pistons may not match exactly; or there could be a variation in the height of the cylinder banks, one being higher than the other or one being higher at one end than it is at the other. Any of these dimensions can vary according to manufacturing tolerances and each must be checked and then corrected so that all measurements of the same kind will be the same.

With these parts then installed in the block, the actual deck clearance can be accurately measured and the block can then be reworked as necessary with a machine for milling the cylinder banks. Specified deck clearance for the V6 is .0256-.0274; for the 155-hp V8, .0150-.0168; and for the 200-hp V8, .0067-.0085. All of these are measured below the surface of the block. For the big car's 401-and 425-cubic-inch engines, the tolerance is .0323-.0341 above the surface of the block.

Connecting rods should be checked first, both for length and diameter, and roundness of the big ends, since any changes in diameter will affect rod bearing clearances. Clearance limits for the V6 and aluminum V8 engines are .0002-.0022, and are the same for the big V8. When setting up for competition, most mechanics will give these bearings clearance on the high side, around .0020, so that the rod will turn more freely on the crankshaft. This allows adequate lubrication without being too loose so as to fling oil into one of the cylinders. Rod and piston alignment also should be checked to insure maximum freedom of movement inside the cylinder.

Crankshaft reworking is best done by companies that specialize in crankshaft stroking and reworking. Variations in main bearing journal and crank pin diameters, roundness and alignment and in stroke length and crank pin spacing should all be corrected and this is usually done by grinding the journals and pins undersize slightly. It is a good idea, too to have the bearing surfaces hard-chrome plated before they are finished to size. This will add to wear resistance and enable all the journals and pins to be finished in their standard sizes. All Buick engines, including the V6, list a main bearing clearance of .0005 to .0021.

Advance casting and machining methods used for production line pistons has practically eliminated the possibility of compression height variations, which is a good deal because variations of any consequence could prove costly. Compression height is measured from the center of the pin bore to the top of the piston head, and this should be checked especially when buying new pistons. The best way to overcome any variations is to exchange the ones that are off so that a matched set can be put together. It is practically impossible, and quite costly, to try and machine dome-type slugs such as those used on the big Buick in order to match them.

Equally important is the installation of pins through the pistons and into the connecting rods. Each of the Buick engines uses a pressed fit and it is vital that they be given ample clearance to prevent any possibility of their binding. A Sunnen hone, used by most shops that specialize in pin fitting, provides the correct pin hole diameter for the best

fit. The V6 and aluminum V8 engines have a recommended pin clearance of .0003 to .0005 in the piston and .0007 to .0015 in the rod. The big V8 lists .0005 to .0001 clearance in the piston and .00075 to .00125 in the rod.

NHRA rules permit an oversize bore of .060-inch, and a great many competitors take advantage of this, since it gives a slight increase in displacement. Engines that are bored the allowable amount should be finished so as to permit fitting of oversize pistons with ample clearance in the cylinder. Blocks that are not bored still should be honed to increase the clearance for standard pistons.

Since reworking of the rod, crank, etc., destroys any balancing that was built in at the factory, it is necessary to completely rebalance the crankshaft assembly before reassembly is started. There are many shops around the country that specialize in precision engine balancing. When the block and crank assemblies are reassembled, it is important that rod caps be installed on the same rod from which it was removed. Bearing inserts must be installed carefully and it is necessary to use a ring compressor when installing piston rings. These should have adequate clearance in their grooves and must be installed with the correct sides up.

NHRA rules prevent grinding or polishing of the valve ports if the engine is to compete in stock classes at the drags but there is considerable rework that can be done to the cylinder heads, including the all-important valve job. If the engine has been run for a long period of time, it is best to check the valve guides and if they are worn, they should be replaced.

Unless you are well skilled with valve grinding equipment, you are better off to leave the major valve work to a specialty shop. A bad valve job can do more to spoil performance than many enthusiasts realize. It is vital, for example, that valve faces be smooth, of the correct angles and concentric with the stems, and seats should be ground a few thousandths of an inch smaller than the diameter of the face for proper seating.

Valve springs should be checked on a special spring testing machine for the correct pressure and also should be straight and of the correct length as specified. This includes the inner springs which are used on the big Buick, though not on the V6 and aluminum V8. Springs that do not measure up to specifications should be replaced. Spring length is measured while the springs are in place on the head. Special shim washers that fit between their lower end and the head are available from most parts houses and are made in different thickness which can be mixed in any way required to increase or reduce spring length where necessary.

The camshaft should be carefully inspected for straightness and, if the engine has been run for any length of time, it is best to check the lobes for signs of wear or damage. Correct alignment of camshaft bearing journals is just as important as the alignment of the crankshaft and its bearings. Care should be taken to prevent the lobes from scratching the soft bearing surfaces during removal or installation.

Finally, the intake manifold heat riser should be blocked with special gaskets for maximum performance. This produces a colder manifold and, consequently, a denser charge of air/ fuel into the cylinders for more efficient combustion. This will affect starting and initial running on cold mornings if the engine is to be subjected to street use, but this generally is secondary to anyone contemplating maximum performance.

Ports in the exhaust manifold or headers should not overlap the exhaust ports in the heads since this tends to disrupt the flow of exhaust gases and causes back pressure. The flow should be as smooth and even as possible.