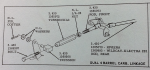

Whenever I see a dual quad throttle linkage it has a spring between the bolt head and the trunnion. The parts book does not show one.

When I look at the linkage, I think if there were a spring here, it would have to be of a specific design and would show in the parts books, which it does not. I have the turnbuckle. On the rounded end, trunnion end, it has a smooth bore hole about 1.125" deep before it has threads. I am suspecting that there may have been some kind of locking device that secures the bolt from turning in the bore.

Probably all wrong, but maybe someone knows!

I have attached the image from the parts book.

Thanks!

When I look at the linkage, I think if there were a spring here, it would have to be of a specific design and would show in the parts books, which it does not. I have the turnbuckle. On the rounded end, trunnion end, it has a smooth bore hole about 1.125" deep before it has threads. I am suspecting that there may have been some kind of locking device that secures the bolt from turning in the bore.

Probably all wrong, but maybe someone knows!

I have attached the image from the parts book.

Thanks!